GOAL

Our client required an automated feeder to orient and transport parts to their automated manufacturing process. One requirement was a rapid parts delivery system. Another requirement was the ability to reject parts that were bad and/or not oriented properly.

SOLUTION

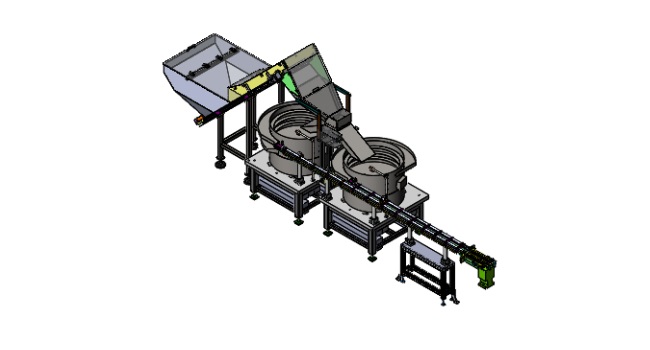

The design employed a hopper to allow the customer to rapidly load their parts. An inclined conveyor transported the parts to either one of the two bowl feeders. Two feeders were required to make the cycle time requirement. After the bowl feeders oriented the parts properly, two inline conveyors moved the parts from the bowl feeders to the start of the customer's process. Sensors monitored the capacity of the conveyors to control the output speed of the bowl feeders while a vision system ensured the parts were good and oriented properly. Parts that did not meet either of those requirements were rejected to a chute located on top of a tote.

SERVICES PROVIDED

- 3D CAD Modeling: Allowed us to identify potential problem areas and improve on the design

- Bill of Material and Cut List: Provided material specs. and size data for quoting and manufacturing

- Detailed Manufacturing Drawings: Provide drawings allowing our client to have their product manufactured